Steel Wear Plate

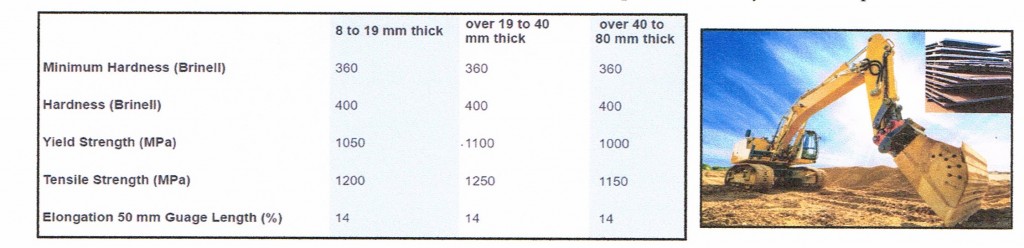

ABRAZO 400 to 600 Abrasion Resistant Plate (High Service Life)

This range of steel plate products have been developed specifically for long service life in abrasive conditions. These products are suitable for a variety of applications in areas such as mining and quarrying, process industries, material handling and construction, and earth moving. This steel in water quenched using a modern roller quenching system that develops higher cooling rates than the traditional platen or static systems. The high cooling rate in combination with optimum chemistry enables elevated hardness levels to be developed whilst maintaining ease of fabrication. This Wear Plate is utilized in applications such as tipper bodies, cutting edges, crushing machinery, and excavator buckets. We can supply this product in thicknesses from 3mm to 150mm, and up to 12 metres by 3 metres in plate size.

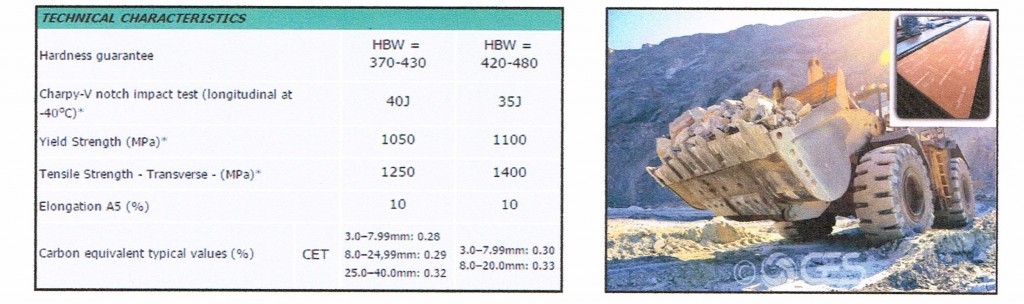

Quard 400 to 600 Steel Plate (Good Workability)

Expirience superior workability during all stages of your manufacturing process, as you will discover how easy it is to work with the unique steel. The homogneous mechanical properties Quard Steel Plate facilitate your work of cutting, bending and welding. Work on Quard Steel Plates is consequently carried out more quickly, reliably and efficiently. When you compare Quard with other steels, you can quickly see how Quard can help you increase your productivity due to lighter design implementation, easier tool preparation and shorter manufacturing time of the finished product.

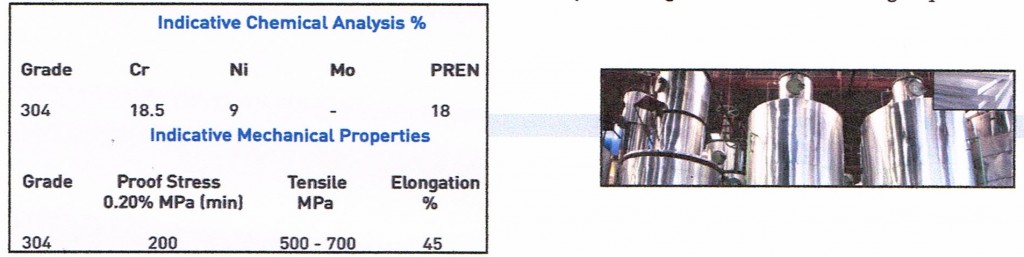

Stainless Steel Plate Type 304

These types of steel are some of the most regularly specified and have come to represent the emgoeiment of the basic stainless product. They are part of the 300 series of steel (as defined in SAE specifications) which covers a range of austenitic chromium-nickel alloys. They are also known as 18/8 stainless due to their chemical composition which includes approximately 18% chromium and 8% nickel by weight. The steels are easy to form, weld, and fabricate and have a high resistance to corrosion. Type 304 and Type 304L have very similar chemical and mechanical properties and are often included on a single material test certificate when the actual properties of a stainless steel plate meet the criteria of both types.

MSS holds a comprehensive stock of plate in large format (up to 12,000 mm long and 3,000 mm wide) which is designed to minimise fabrication costs for our customers by reducing the amountof welding required.

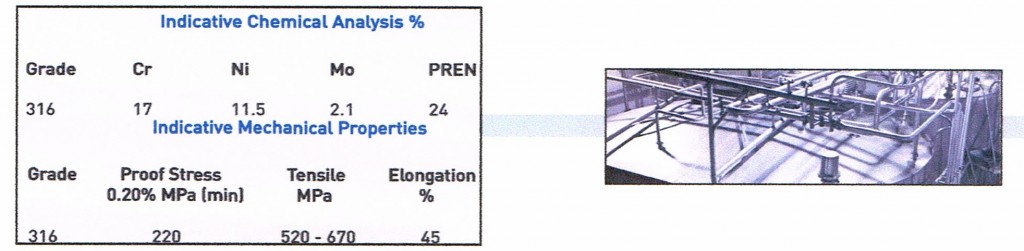

Stainless Steel Plate Type 316

These steels are th second most regularly specified stainless steels after Type 304 and are part of the SAE defined 300 Series which encompasses a range of austenitic Chromium-Nickel Alloys. Austenitic stainless steels like Type 316 are widely available, have good general corrosion resistance, good cyrogenic toughness, and excellent formability and weld ability. Type 316 has 2-3% Molybdenum included in its chemical composition which prevents specific forms of corrosion and generally enhances its corrosion resistance. MSS stainless steel stock is made up of large area plate sizes (up to 12,000 mm long and 3,000 mm wide) which means there is the greatest possible opportunity for us to ensure the best plate utilisation when cutting shapes and components to customers’ requirements. This makes sure that scrap is kept to a minimum and prices are kept low.

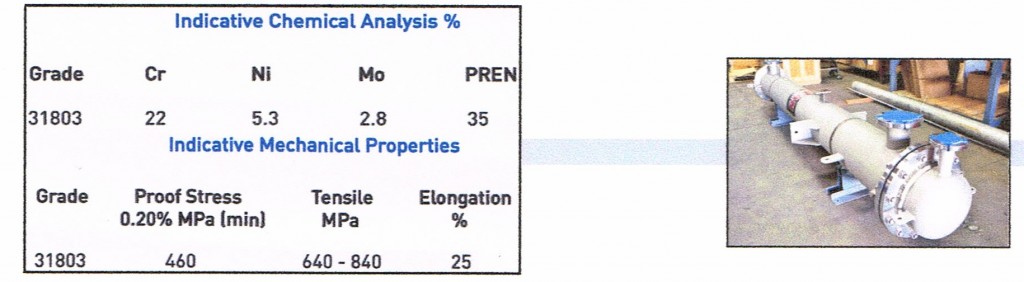

Duplex Stainless Steel Plate

Duplex Stainless Steel was developed as a product which could improve upon some of the technical weaknesses of the standard austenitic and ferritic stainless steels that are available in the market. Duplex Stainless has a microstructure which is split roughly 50:50 between austenite and ferrite and balancing of these phases provides the following benefits:

- Higher strength which is around twice that of Type 304 austenitic stainless steel.

- Good weld ability in thick plates

- Good low temperature toughness

- Resistance to stress corrosion & cracking. MSS can supply grades S31803,S32205, and 1.4462.